Press Release – MEMS vs. Crystal Oscillators

MEMS vs. Crystal Oscillators: It’s All in the Application

Putting timing and frequency control technologies in their proper place

Ron Stephens, Q-Tech Corporation, www.XOProf.com

Introduction

Precision frequency control and timing are essential to all modern electronics technology. Almost every electronic device you can imagine depends on a precision clock; without precision oscillator clocks, all electronic communication would stop.

This article compares the benefits of the latest precision clock technologies as they perform in different applications.

The Evolution of Precision Clocks

Introduced in the 1920’s, the quartz crystal oscillator has long been the workhorse amongst electronic timing devices. A newer type of oscillator that has been in development since the 1960s and available in production volumes since 2005, is the Micro-Electro-Mechanical-System (MEMS) resonator clock.

Today, MEMS oscillators have somewhat replaced crystal oscillators in many high-volume, low-cost applications. Like many things in the technology world, however, there are trade-offs and exceptions to be considered depending on the application where the device is being used.

Tradeoffs: MEMS Vs. Crystal Oscillators

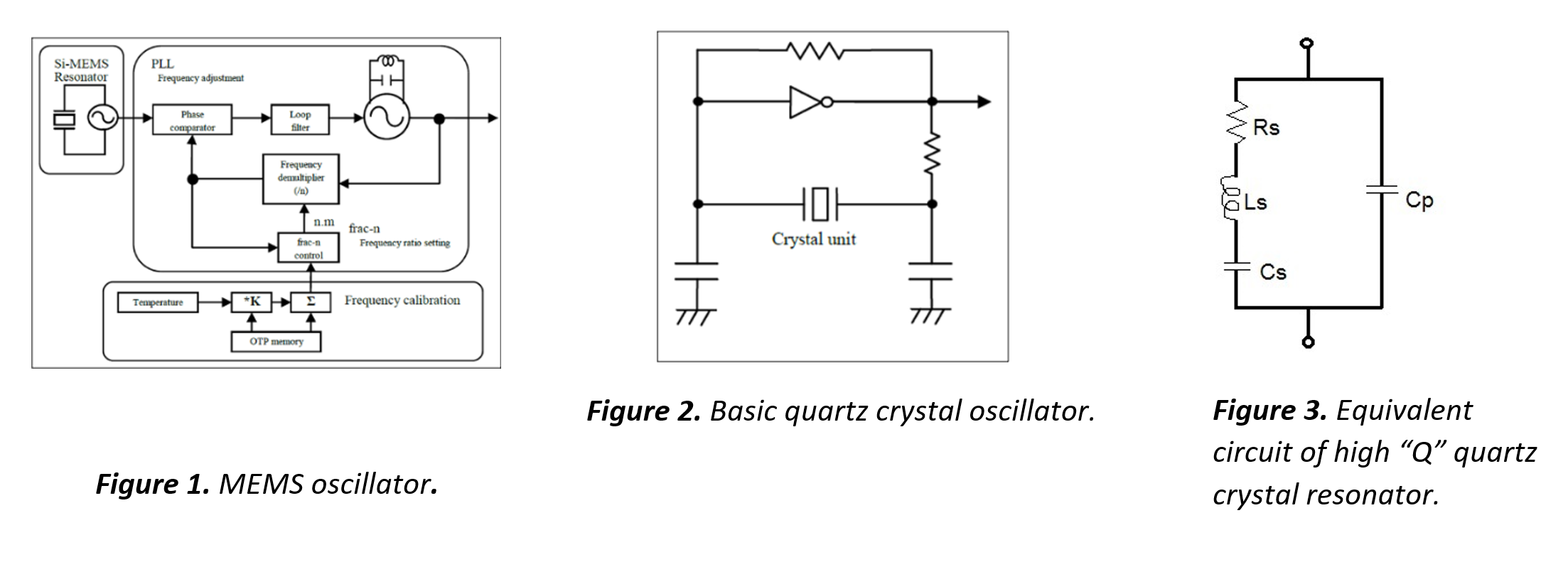

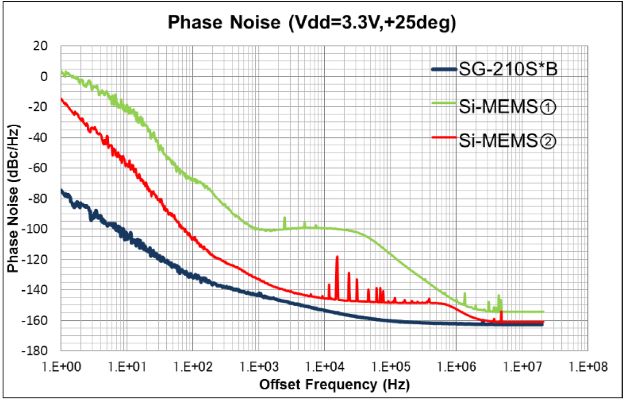

To better understand their differences, Figures 1 and Figure 2 show block diagrams of the MEMS oscillator and the crystal oscillator circuit. The MEMS oscillator is more complicated. In addition to a micromechanical silicon resonator, its digital circuitry includes a PLL to determine and control frequency.

In comparison, the crystal oscillator is very simple and depends heavily on the very high “Q” quartz crystal resonator as the sole frequency-determining element shown in Figure 3.

Both MEMS and crystal oscillators can be made more precise by using temperature compensation to achieve less than 1 PPM stability or oven-control to achieve PPB levels of stability. In common parlance, crystal oscillators utilizing these compensation methods are referred to as TCXOs and OCXOs, respectively. And while the “XO” is specifically used for crystal oscillators, these terms are often used to refer to similarly compensated MEMS.

In terms of absolute frequency stability over temperature, manufacturers are achieving great improvements in MEMS performance. SiTime, for example, is making MEMS that are almost arbitrarily precise by means of digital compensation techniques.

The following discussion gets to the heart of the performance tradeoffs between quartz crystal oscillators and MEMS oscillators.

Phase Noise and Jitter

MEMS can withstand higher shock levels and are less susceptible to vibration sensitivity than quartz clocks. Since quartz resonators have a relatively larger mass, they also may experience fractures under very high shock levels.

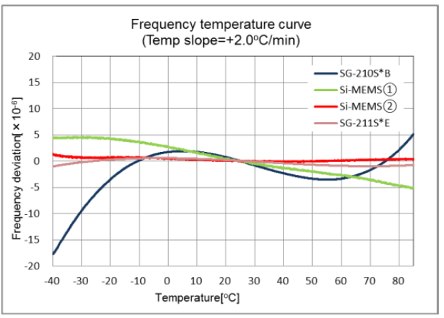

Figure 4 shows a comparison of phase noise for MEMS and quartz crystal oscillators. While MEMS can be made extremely precise in terms of stability, and while they are improving the phase noise and jitter performance, they can never be as good as quartz for static phase noise, jitter and some other short-term stability parameters. A benefit inherent to quartz crystal oscillators is their much higher “Q” level, which results in lower phase noise and lower jitter; so, in applications where this is important, quartz still reigns supreme.

Also, the improved phase noise and jitter performance for MEMS always comes at the cost of even more power consumption. Quartz oscillators are more efficient and reliable than MEMS devices whose complex circuitry consumes more power and can result in slower start-up times. Moreover, quartz clocks can survive higher doses of radiation since MEMS clocks contain a non-radiation tolerant Phase Lock Loop (PLL).

Figure 4. Phase noise comparison of a quartz crystal oscillator vs. two equivalent MEMS oscillators.

Temperature Stability

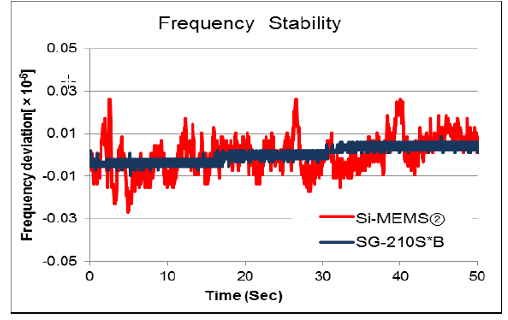

Figures 5 and 6 illustrate the reasons behind the most important tradeoffs between MEMS and quartz oscillators. Figure 5 shows the frequency vs. temperature performance of typical quartz oscillators compared to comparable MEMS devices. The first impression from this figure may be that MEMS oscillators actually demonstrate better frequency vs. temperature performance.

However, upon closer inspection, Figure 6 shows that, over time, the MEMS oscillators have frequency jumps whenever the division ratio switches to compensate for temperature changes. The high “Q” quartz crystal gives an inherently stable and smooth curve.

Figure 5. Comparison of frequency stability of quartz crystal vs. MEMS oscillators.

Figure 6. MEMS frequency stability exhibits frequency jumps unlike crystals.

The MEMS resonator can be digitally corrected to be almost any level of stability –but at the cost of increasing power consumption. And it will always have many micro frequency jumps over every short-term cycle that must be digitally corrected back to the desired level of stability. Thus, the curve is not smooth; it has a large number of small frequency jumps due to the dithering caused by digital correction. If more power is used, the dithering can be reduced, but never eliminated. This is what causes the MEMS clock to have worse phase noise and jitter than quartz crystal oscillators.

Manufacture and Cost

MEMS clocks offer several advantages over crystal oscillators in cost, production volume and lead time. Because quartz crystal oscillators are inherently “custom,” MEMS clocks are usually much cheaper and faster to produce. Also, MEMS are manufactured in very high volumes using semiconductor manufacturing methods.

Therefore, applications that do not need the good phase noise and the low jitter benefits of quartz, can tolerate the higher power consumption, and that will not be exposed to any radiation, will often use the much less expensive MEMS.

Conclusion

Both technologies have their place in the future. On balance, MEMS oscillators already have very good performance and are an extremely valuable technological advancement that will continue to be improved. They will dominate in high-volume low-cost clock applications, most notably in the automotive industry where low phase noise is not important. For their part, quartz crystal oscillators will continue to dominate space applications (where using MEMS is not a possibility), as well as RF and microwave applications, radar and other noise-sensitive circuits.

About Q-Tech

Q-Tech Corporation was founded in 1972 with the objective of providing state-of-the-art crystal clock oscillators and frequency control solutions for companies with demanding applications. As the leading U.S. manufacturer of qualified products to MIL-PRF-55310 as well as ultra-high reliability standards such as Aerospace Corporation TOR (GPS III) and NASA GSFC specifications, Q-Tech proudly services the military, aerospace, down-hole and deep space industries. Q-Tech is certified to the AS9100 and ISO 9001 Quality Management Systems. The Company maintains a global presence with sales capabilities throughout North America, Europe, and Asia. The Axtal acquisition integrates the company’s European-based engineering development and ISO9001:2015 manufacturing facilities.

XO Prof Website: Here

Click Here for downloadable PDF copy of this article.